| Clean Aire HEPA/Carbon In-Line Filtration Systems |

|

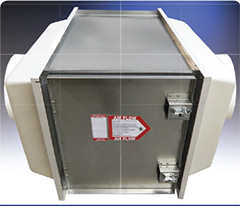

Clean-Aire HEPA and Carbon Filter Packs are designed to be mounted incline in the exhaust ducting from a fume hood or contaminant source up to 1500 cfm.

The filter pack includes a galvanized steel housing with hinged and gasketed access door for filter change-out and molded composite resin inlet and outlet plenum with duct connection collars sized to meet specification.

Both filters include a 30% pleated prefilter and can be paired together for applications that require particulate and fume removal. |

|

|

|

| Clean Aire In-Line HEPA Filtration Systems |

|

HEMCO HEPA filter packs effectively collect particulate contaminants from the exhaust air stream. HEPA filters are 99.999% effective at removing particulate .3 micron and larger. The filter pack housing features a hinged access door with gaskets and spring latches for convenient filter change. Inlet and outlet plenum's with duct connection collars are installed. The HEPA

filter pack can also be paired with a carbon filter pack to remove chemical fumes and odors. |

|

| Note: HEMCO recommends a minihelic or magnehelic gauge to monitor the airflow differential across the filter. The static pressure indicated would alert when to change filter. The gages can be hood or filter mounted. We recommend ordering a back-up replacement filter. |

|

|

| Clean Aire HEPA Filter Pack |

| CFM |

Size |

Duct Size |

Cat. No. |

| 250-650 |

26” x 15” x 35 1/2” |

4”, 6”,8” diameter |

50188 |

| 650-1200 |

26” x 26” x 35 1/2” |

8”, 10”, 12” diameter |

50189 |

| HEPA Filters |

Prefilter (6 per carton) |

| CFM |

Size |

Cat. No |

CFM |

Size |

Cat. No. |

| 500 |

24” x 12” x 12” |

50094 |

500 |

24” x 12” x 2” |

52000 |

| 1000 |

24” x 24” x 12” |

50095 |

1000 |

24” x 24” x 2” |

52001 |

|

|

| Shown with optional photohelic gauge Cat. No. 51302 |

|

| HEPA Filter Bag In Bag Out System |

|

| Filter Housing is fabricated of type-304 stainless steel & requires (1) carbon filter absorber, (1) 24” X 24” X 2” 30% pleated prefilter & (1) bag. |

|

| Bag-In bag-out filters are designed to meet air filtration requirements to handle hazardous fumes and vapors. The housing incorporates a ribbed bagging ring around the side access door over which a specially designed plastic bag is attached. Filters are then installed and changed through the bag to reduce the risk of exposure to personnel |

|

|

| Clean Aire HEPA Filter Bag-In Bag-Out System |

| Description |

CFM |

Size |

Cat. No. |

| Clean-Aire HEPA Filter Bag-In Bag-out System |

1000 |

26” X 26” X 35-1/2” |

51189 |

| HEPA Filters |

1000 |

24” X 24” X 12” |

50195 |

| HEPA Prefilter (6 per carton) |

1000 |

24” X 24” X 2” |

52001 |

| Replacement Bags (2 per carton) |

51989 |

|

|

Minihelic Gauge

Gauge monitors the pressure differential across the HEPA filter, Gauge conveniently mounts on the fume hood or on the filter

housing. Measure range is from 0 to 2.0” wg Gauge is 3” dia. with 5% accuracy Cat. No. 51300 |

|

Magnehelic Gauge

Gauge measures static pressure across the HEPA filter. Mounts on the fume hood or the filter housing. Range of measurement is

from 0 to 2” wg. Gauge is 5” dia with 2% accuracy. Cat. No. 51301 |

|

| Clean Aire In-Line Carbon Filtration Systems |

|

HEMCO carbon filter packs are used in laboratory exhaust and supply systems to remove chemical odors and vapors from the airstream. Filters are loaded with virgin coconut activated carbon to efficiently absorb organic solvents and acid fumes. The

filter pack housing features a hinged access door with gaskets and spring latches for convenient filter changes. Inlet and outlet plenum's with duct connection collars are installed. The carbon filter pack can also be paired with a HEPA filter pack to collect particulate contaminants. |

|

| A standard “01” activated carbon filter for organics is included. HEMCO recommends the sampling kit to check if there has been a breakthrough in the carbon filter, and ordering a back-up replacement filter. |

|

|

| Clean Aire Carbon Filter Pack |

| CFM |

Size |

Duct Size |

Cat. No. |

| 250-650 |

26” x 15” x 35 1/2” |

4”,8” diameter |

50297 |

| 650-1200 |

26” x 26” x 35 1/2” |

8”, 10”, 12” diameter |

50298 |

| Carbon Filters |

Prefilter (6 per carton) |

| CFM |

Size |

Cat. No |

CFM |

Size |

Cat. No. |

| 500 |

24” x 12” x 12” |

52100 |

500 |

24” x 12” x 2” |

52000 |

| 1000 |

24” x 24” x 12” |

52101 |

1000 |

24” x 24” x 2” |

52001 |

|

|

| Carbon Filter Bag In Bag Out System |

|

| Filter housing is fabricated of type-304 stainless steel & requires (1) carbon filter absorber, (1) 24” X 24” X 2” 30% pleated prefilter & (1) bag. |

|

| Bag-In bag-out filters are designed to meet air filtration requirements to handle hazardous fumes and vapors. The housing incorporates a ribbed bagging ring around the side access door over which a specially designed plastic bag is attached. Old filter is removed then new filters are then installed and changed through the bag to reduce the risk of exposure to personnel. Note: The carbon filter is not included with the housing. We also, recommend the sampling kit below to check if there has been a break through in the carbon filter, and ordering a back-up replacement filter. |

|

|

| Clean Aire Carbon Filter Bag-In Bag-Out System |

| Description |

CFM |

Size |

Cat. No. |

| Clean-Aire Carbon Filter Bag-In Bag-out System |

1000 |

26” X 26” X 35-1/2” |

51198 |

| Carbon Filters |

1000 |

24” X 24” X 12” |

52111 |

| Carbon Prefilter (6 per carton) |

1000 |

24” X 24” X 2” |

50001 |

| Replacement Bags (2 per carton) |

51999 |

|

|

| Clean Aire In-Line Filtration Systems |

|

| The filtration system is rated at 1800 cfm & includes a stainless steel housing with lift off and gasketed access doors for filter change-out and inlet & outlet plenum with duct connection collars sized to meet specification. Bubble tight dampers allow system to close off for filter change. |

|

• Initial filters supplied (excludes prefilters)

• Initial change out bags supplied.

• Inlet/outlet duct connection flanges shall be

a minimum of 1-1/2” wide.

• Approx. shipping weight: 1100 LBS.(without filters)

• Approx. operating weight: 1350 LBS.

• A minimum of four (4) feet of clearance in front

of access door is recommended for filter

change-out.

Cat. No. 58998-1 (1) HEPA and Carbon Incline

Cat. No. 58998-2 (2) HEPA and Carbon Online

|

|

|

|

The following chart is a partial list of contaminants and the proper type of carbon for maximum efficiency. For additional contaminants,

please consult factory. *Filter Check Available |

|

Contaminant |

Type |

Contaminant |

Type |

Contaminant |

Type |

Contaminant |

Type |

Contaminant |

Type |

Acetic Acid |

01 |

Chlorophicbin |

01 |

Ethylene Dichloride |

01 |

Iodine |

01 |

Propyl Mercaptan |

01 |

Acetone |

01 |

Formaldehyde |

01 |

Ethylene Oxide |

06 |

Isopropyl Alcohol |

01 |

Pyridne |

01 |

Ammonia* |

05 |

Cyclohexanone |

01 |

Formaldehyde |

03 |

Isopropyl Ether |

01 |

Styrene Monomer |

01 |

Benzene |

01 |

Dibromoethane |

01 |

Formic Acid* |

02 |

Methyl Butyl Keytone |

01 |

Sulfur Dioxide* |

02 |

Butyl Acetate |

01 |

Dichloronitroethane |

01 |

Formaldehyde |

04 |

Methyl Ethyl Keytone |

01 |

Sulfuric Acid* |

02 |

Caprylic Acid |

01 |

Dichloropropane |

01 |

Heptane |

01 |

Methylene Chloride |

01 |

Toluene |

01 |

Carbolic Acid |

01 |

Dimethyl Sulfate |

01 |

Heptylene |

01 |

Nitric Acid* |

02 |

Trichloroethalene |

01 |

Carbon Tetrachloride |

01 |

Dipropyl Keyton |

01 |

Hexane |

01 |

Nitrobenzene |

01 |

Trichloroethane |

01 |

Chlorine* |

02 |

Ethyl Alcohol |

01 |

Hydrogen Bromide* |

02 |

Nitropropane |

01 |

Xylene |

01 |

Chloroform |

01 |

Ethyl Benzene |

01 |

Hydrogen Chloride* |

02 |

Octalene |

01 |

|

|

|