| Fume Hood Exhaust Blowers |

|

| A complete line of belt and direct drive exhaust blowers that are chemical resistant & available in standard and explosion-proof models. HEMCO blowers are designed to operate effectively and efficiently to remove noxious & hazardous fumes. Standard 115V 60Hz international electrical configuration of 220V 50Hz AC available. |

|

|

1. Blowers should be mounted on the roof in-order that the ducting leading to the blower inlet is under negative static pressure. If exhaust blowers are mounted inside the building, all ducting connected to the blower outlet will be under positive static pressure, if a leak were to develop in the section of the duct inside the building, toxic & or hazardous fumes could be forced out of the ductwork and into that area of the building.

2. To achieve the lowest practical noise level in the exhaust system, we suggest that the following measurements be

used when there is no conflict with

other specifications

of the system:

a. Use vibration isolators or mounting blower exhaust assembly.

b. Install a blower fan that will deliver the correct CFM and

static pressure with the lowest practical impeller wheel RPM.

If possible, use a duct size large enough to keep duct velocity under 1800 FPM velocity.

c. Use a flexible connection at the fan inlet to isolate mechanical transmission of noise from the ducting between the hood and the exhaust blower. |

|

d. Exhaust blower system should be designed with the fewest possible elbows or other fittings. Use radius type elbows & avoid using square elbows. Use gradual tapered transitions where necessary, & avoid abrupt changes in configuration or cross sectional area.

3. When ordering an exhaust blower, specify the orientation of discharge desired. Vertical up blast discharge is the most common and will be supplied unless otherwise specified.

4. All fans are shipped with clockwise rotation when viewed from the motor end of the assembly.

5. For normal usage, the standard for both the blower housing and impeller wheel is epoxy coated.

6. Blowers used for hood exhaust at altitudes above 1,000 feet, may require a correction factor to provide the correct CFM and static pressure.

Contact factory for details relating to your specific application. |

|

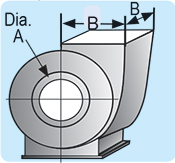

| Epoxy Coated Steel Blower Belt Drive |

|

|

Standard (STD) belt drive steel blower and impeller wheel are epoxy coated for superior chemical resistance. Explosion-proof blowers (EXP) have epoxy coated, non-sparking aluminum impeller wheel. V-belt drive and adjustable pulleys permit field balancing. Seven discharge positions to suit installation. Weather housing is furnished. Motor has thermal overload protection. Specify: 115 V single phase, 230 V single phase, 230/460 V three phase or 208 V (consult factory). 1 year manufacturer’s warranty |

| Catalog Number and Static Pressure |

| cfm |

A

Inlet

Diameter |

B

Outlet

Size |

1/2” Static Pressure |

3/4” Static Pressure |

1” Static Pressure |

1 1/2” Static

Pressure |

| HP |

STD |

EXP |

HP |

STD |

EXP |

HP |

STD |

EXP |

HP |

STD |

EXP |

| 296 |

8 7/8” |

10 1/8” x 4 1/8” |

1/4 |

51701 |

51801 |

1/4 |

51702 |

51802 |

1/4 |

51703 |

51803 |

1/4 |

51704 |

51804 |

| 474 |

8 7/8” |

10 1/8” x 4 1/8” |

1/4 |

51705 |

51805 |

1/4 |

51706 |

51806 |

1/4 |

51707 |

51807 |

1/2 |

51708 |

51808 |

| 652 |

8 7/8” |

10 1/8” x 6 3/8” |

1/2 |

51709 |

51809 |

1/2 |

51710 |

51810 |

1/2 |

51711 |

51811 |

1/2 |

51712 |

51812 |

| 800 |

8 7/8” |

10 1/8” x 6 3/8” |

1/2 |

51713 |

51813 |

1/2 |

51714 |

51814 |

1/2 |

51715 |

51815 |

3/4 |

51716 |

51816 |

| 914 |

9 7/8” |

11 1/2” x 8 1/4” |

1/2 |

51717 |

51817 |

3/4 |

51718 |

51818 |

-- |

-- |

-- |

-- |

-- |

-- |

| 1044 |

9 7/8” |

11 1/2” x 8 1/4” |

1/2 |

51719 |

51819 |

1/2 |

51720 |

51820 |

1/2 |

51721 |

51821 |

-- |

-- |

-- |

| 1175 |

9 7/8” |

11 1/2” x 8 1/4” |

1/2 |

51722 |

51822 |

1/2 |

51723 |

51823 |

3/4 |

51724 |

51824 |

-- |

-- |

-- |

| 1240 |

9 7/8” |

11 1/2” x 8 1/4” |

1/2 |

51725 |

51825 |

1/2 |

51726 |

51826 |

3/4 |

51727 |

51827 |

3/4 |

51728 |

51828 |

| 1240 |

11 7/8” |

13 3/8” x 8 1/4” |

1/3 |

51729 |

51829 |

1/2 |

51730 |

51830 |

-- |

-- |

-- |

-- |

-- |

-- |

| 1506 |

11 7/8” |

13 3/8” x 8 1/4” |

3/4 |

51731 |

51831 |

3/4 |

51732 |

51832 |

3/4 |

51733 |

51833 |

-- |

-- |

|

| 1771 |

11 7/8” |

13 3/8” x 8 1/4” |

1 |

51734 |

51834 |

1 |

51735 |

51835 |

1 |

51736 |

51836 |

1 1/2 |

51737 |

51837 |

|

|

|

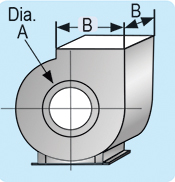

| Epoxy Coated Steel Blower Direct Drive |

|

|

Direct drive steel blower and impeller wheel are epoxy coated for superior chemical resistance. Explosion proof blowers have epoxy coated non-sparking aluminum impeller wheels. Motor is 115V, 1 phase and has thermal overload protection. 1 year manufacturer’s warranty |

| Catalog Number and Static Pressure |

A

Inlet

Diameter |

B

Outlet

Size |

HP |

STD |

EXP |

1/4” SP |

1/2” SP |

3/4” SP |

1” SP |

| cfm |

cfm |

cfm |

cfm |

| 6” |

7” X 4-3/8” |

1/6 |

51177 |

51178 |

565 |

515 |

440 |

300 |

| 8” |

8-3/4” X 5-7/16” |

1/3 |

51179 |

51180 |

935 |

875 |

800 |

712 |

| 9” |

10-1/8” X 4-1/8” |

1/2 |

51181 |

51182 |

1050 |

980 |

920 |

850 |

| 9” |

10-1/8” X 5-1/8” |

3/4 |

51183 |

51184 |

1260 |

1220 |

1180 |

1100 |

|

|

| Standard motors are 115V, 60Hz / 1 phase. Explosion proof motors are 115/230V, 60Hz, 1 phase. Other voltage, hertz, and phase motors are available. |

|

| Fume Hood Exhaust Blowers Ordering Info |

|

| HEMCO offers a complete line of chemical resistant non-metallic exhaust blowers in belt drive or direct drive options in standard or explosion proof models. Ideal for applications where corrosion resistance is critical. These blowers are available in polypropylene or fiberglass construction. |

|

|

1. It is recommended that exhaust blowers be located at the

end of

the ducting which is typically roof mounted. This ensures a negative pressure through out the ventilation system. However for applications

where the duct is going directly out through a wall above a fume hood,one option is to have a fiberglass direct drive blower installed in the top of the fume hood. By having the blower internally mounted, the installation is simplified and convenient for duct connection and servicing. However there would be an airflow sound element associated to having the blower hood mounted.

|

|

2. By keeping the exhaust duct as short and as straight as possible,

the total resistance will be reduced and by keeping the diameter of

the duct correctly sized to the flow volume, noise and static

pressure can be reduced.

3. Blower wheels for polypropylene and fiberglass blowers are polypropylene.

4. Vibration isolators are recommended when mounting the

blower assemblies

5. HEMCO recommends that a sash stop be installed on the fume hood to limit the sash height for operation. By having

stop at a half open position, the total CFM can be reduced by 50%; thus by reducing the volume, energy loss, duct diameter, motor and blower size, and sound is reduced. |

|

|

| UniFlow SE & LE Fume Hoods |

Hood

Width |

Hood

Depth |

Full

Open cfm |

1/2

Open cfm |

| 36” |

30” |

438 |

241 |

| 48” |

30” |

772 |

385 |

| 60” |

30” |

938 |

474 |

| 72” |

30” |

1162 |

592 |

| 96” |

30” |

1613 |

800 |

| UniFlow CE Fume Hoods |

Hood

Width |

Hood

Depth |

Full

Open cfm |

1/2

Open cfm |

| 30” |

24” |

378 |

189 |

| 36” |

24” |

460 |

230 |

| 48” |

24” |

654 |

327 |

| 72” |

24” |

960 |

480 |

|

• CFM at 100 fpm face velocity

• Housing is constructed of heavy gauged galvanized steel, with a baked enamel

finish, to resist weather & chemical exposures.

• Flange inlet collars enable easy connection to ductwork.

• Wheel is dynamically balanced to minimize noise and increase efficiency.

• Ball bearing pillow blocks are per-lubricated and resistant to both moisture & dirt.

• Shaft is constructed of polished steel with a coating to prevent rust and corrosion.

• Motors meet NEMA standards for single speed motors.

• These blowers are ideally suited for both supply and exhaust applications in

laboratories, educational, pharmaceutical, industrial, and other applications. |

|

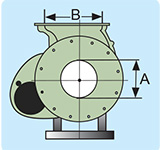

| Polypropylene Belt Drive Blowers |

|

|

High efficiency impellers produce low power consumption, reduced operating costs and quiet operation. 20 forward curved blades, in fire retardant polypropylene. Non-static and oil resistant v-Belt, cast iron pulleys, adjustable pulleys available, adjustment for tensioning and belt replacement. 230V explosion proof, non sparking, chemical resistant for hostile or hazardous environments. 115V single phase or three phase. Non-static and oil resistant V-belt, cast iron pulleys, adjustable pulleys available, adjustment for tensioning and belt replacement.

1 year manufacturer’s warranty |

|

| Catalog Number and Static Pressure |

| cfm |

A

Inlet

Diameter |

B

Outlet

Diameter |

0.5” Static Pressure HP |

0.75” Static Pressure HP |

1.0” Static Pressure HP |

| HP |

STD |

EXP |

HP |

STD |

EXP |

HP |

STD |

EXP |

| 400 |

6” |

6” |

1/4 |

51450 |

51850 |

1/4 |

51460 |

51860 |

1/4 |

51470 |

51870 |

| 800 |

8” |

8” |

1/4 |

51451 |

51851 |

1/3 |

51461 |

51861 |

1/3 |

51471 |

51871 |

| 1000 |

8” |

8” |

1/2 |

51452 |

51852 |

1/2 |

51462 |

51862 |

1/2 |

51472 |

51872 |

| 1200 |

10” |

10” |

1/2 |

51453 |

51853 |

1/2 |

51463 |

51863 |

1/2 |

51473 |

51873 |

| 1600 |

10” |

10” |

1 |

51754 |

51854 |

1 |

51464 |

51864 |

1 |

51474 |

51874 |

|

|

| Variable Motor Speed Drive |

|

.jpg) |

|

Motor speed control can be used to manually adjust blower cfm. Adjustable speed control for 3-phase motors 3/4 to 10 horsepower at 230/460 volts and 50/60Hz. these drives provide high operation efficiency and constant input power factor throughout the entire speed range of 3 to 60Hz. Drives are rugged, reliable and backed by years of manufacturing and application experience in motors and controls. These drives are tailored to the variable torque loads in fans or fume hoods.

1/2 -5HP 230V 3ph, 50/60 Hz.....................................................................................Cat.No. 51402 |

|