|

|

| .....HEMCO is the leading manufacturer of innovative laboratory equipment serving the Sciences and R&D Technology Industries since 1958. Located in Independence, Missouri, the heart of America, and the crossroads of North America a major center for transportation, communication, distribution, and manufacturing industries worldwide. |

| .....HEMCO also known as Hill Engineering and Manufacturing Company's modern manufacturing and distribution facilities combined with our many years of experience uniquely qualifies us to provide laboratory planning solutions. Our extensive engineering, design and manufacturing expertise can transform your laboratory ideas into reality. |

|

|

|

HEMCO celebrates it's 68th anniversary in 2026.

....."This is quite an accomplishment for a small start up business. We were honored by the Mayor of Independence. 2008 was our 50th year, and we look forward to continued growth and service to the industries we serve.

....."One of our most important associations over the past 30 years is our membership in SEFA (Scientific Equipment & Furniture Association) which this year marks SEFA's 30th anniversary. HEMCO is proud to be one of the founding members since 1988. SEFA is a growing and preferred association that represents all Laboratory Fume Hood Furniture Manufacturers worldwide. |

Ronald E. Hill P.E.

CEO & Co-Founder |

|

...HEMCO's Membership in Technical Associations, Inspires Innovation

..The year 2009 marked a new beginning for HEMCO, we became an ISO 9001:2008 certified company. In 2018 HEMCO became an ISO 9001:2015 certified company. The International Standard Organization is recognized in the USA and 178 countries worldwide. HEMCO's management team has adopted the ISO quality management and procedures into our daily operating system. By continuing to improve manufacturing procedures & operations, it creates efficiency with employee involvement. "We say what we do and we do what we say" We strive to make our customers experience number 1, with our prompt service. Completing projects on time and within budget.

.....The next year, 2010, HEMCO's UniFlow SE Aire Stream, UniFlow LE & UniFlow CE fume hoods became U.L. classified to U.L.1805 standards for laboratory fume hoods & cabinets. Underwriter Laboratories have 69 labs and certified testing facilities in the US, and over 100 countries worldwide, with 6,600 employees to service the U.L. clients. U.L. has tested HEMCO HiPel composite fiberglass laminate for chemical & flame resistance and to NFPA 45 for plastics suitable to use in the laboratory. All of HEMCO's fume hoods are tested to meet U.L. standard 3101 for electrical circuitry & are listed and compliant to U.L.1805 -3101, CSA, and CE classifications.

.....Consider HEMCO UniFlow Fume Hoods on your next lab project.

....................Thank You and as Always Welcome to HEMCO

|

|

|

|

National Society of

Professional Engineers & MSPE

Lifetime Member |

|

Scientific Equipment & Furniture Association Founding Member

Lifetime Member |

|

American Chemical Society

Chemical Health & Safety

Member Since 1989 |

|

International Society of

Pharmaceutical Engineers

Member Since 1994 |

|

American Society of

Heating, Refrigeration & Air Conditioning Engineers

Lifetime Member |

|

International Institute for

Sustainable Laboratories

Member Since 2002 |

|

UL Underwriters Laboratories Certified 1805 and 3101

Since 2010 |

|

ISO 9001:2015

Certified Company

Since 2009 |

|

American Institute

of Architects

Member Since 2013 |

|

Association

of Energy Engineers

Member Since 2012 |

|

National Fire

Protection Association

Member Since 2012 |

|

|

AireStream Laboratory Fume Hoods |

|

|

|

HEMCO offers a complete line of UniFlow laboratory fume hoods. Bench-mounted hoods in widths from 24” to 96”. Floor-mounted (walk-in) hoods from 48” to 144” wide and up to 96” deep. UniFlow fume hoods are designed for performance, user protection, & save 50% on reduced energy cost. |

|

U.L., Underwriters Laboratory U.L. 1805 for fume hoods & cabinets, this classification covers construction, materials, flammability, & containment. U.L. 3101 electrical performance is tested using HIPOT testing, (high potential high voltage). HEMCO’s test facility is compliant to test fume hoods for U.L.1805 Classification |

|

CSA, Canadian Standards Associations CAN/CSA - C22.2 compliant for electrical components |

|

CE European Community Configured International Electrical Services. |

|

OSHA, Occupational Health & Safety Federal Register 29 CFR part 1910 |

|

SEFA, Scientific Equipment Furniture Association, SEFA 1-2010 recommended practices for fume hoods |

|

ASHRAE, American Society of Heating, Refrigerating & Air-Conditioning Engineers, ASHRAE - 110, 1995 |

|

ANSI, American National Standards Institute, Z9.5, 2012 Laboratory Ventilation |

|

ASTM, American Society for Testing and Materials ASTM E-84, 2001 |

|

NFPA, National Fire Protection Association, NFPA - 45, 2000 |

|

UniFlow Fume Hoods are listed on |

|

|

5 year warranty on all UniFlow SE, LE & CE AireStream

models which are U.L. 1805 classified, guaranteed |

|

New UniFlow SL AireStream Fume Hoods UniFlow fume hoods are designed for performance, user protection. With exclusive Vector airflow slots to maintain airflow through the fume chamber. |

|

|

|

|

| Advantages of UniFlow CAV By-Pass Fume Hoods |

| 1. Important: by incorporating Sash Management 1-2-3, you are saving 50% on overall energy costs, and providing the best possible user protection safety. |

2. Recommended that hoods be used with sash 1/2 open with face velocity of 80-100 FPM. Sash stop located at 1/2 open position. With upper sash raised to the 1/2 open position the supply air CFM static

pressure are as noted. |

| 3. Sash in full open position should be for setup of apparatus and maintenance service only. If design opening is at 1/2 open at 100 FPM, face velocity at full open would be approximately 50 FPM. The recommended face velocity for efficiency & safety is 80-100 FPM Lower face velocity may compromise user safety.

|

| 4. When hood is not in use, keep sash in closed position. |

| 5. Sash stops are standard on U.L. Classified Fume Hoods. UniFlow SE, LE and CE AirStream fume hoods |

6. The Sash Stop is designed for user protection and CFM reduction.

Allows sash to open to a maximum of half open, providing up to 50%

energy savings. |

7. Sash at full open is primarily designed for set-up of equipment

and maintenance. Fume hood users should wear personal safety

protection equipment, consult lab safety officer. |

| 8. HEMCO recommends 10-12 room air changes per hour for the health & safety of personnel. Example 10’ X 20’ room 10’ high receiving 10 room air changes per hour requires 350 CFM air flow through the lab. |

| 9. At an average utility rate of $7.00 per CFM, a typical annual savings on a 4’ fume hood would be $2705.00 and on a 6’ fume hood $4067.00, by using Sash Management 1-2-3., Sash Stop at 50% open. |

|

|

| Traditional Fume Hoods vs UniFlow Fume Hoods |

| Innovation is the Difference Between the Same Perspective and an Entirely New one. |

| |

|

|

|

| |

The 1925 Ford Tri-motor, featured all metal construction, no wood. Its fuselage and wings were constructed of corrugated sheet metal, for strength. These aircraft were well-designed, and reliable

(for the era). |

|

The Boeing 787 Dreamliner features aerodynamic composite construction. Composites have a higher strength to weight ratio, which helps to make the 787 a lighter more energy efficient aircraft. |

|

| Traditional Fume Hoods |

|

1. Fully Assembled Fume Hoods |

|

UniFlow Fume Hoods |

|

|

Traditional Fume Hood 60” wide Constructed of formed painted sheet metal panels & held together with sheet metal fasteners & brackets. Chemical resistant interior liner panels with sharp corners sealed with caulking.1 year warranty. Heavy challenging installation.

Weight 435 lbs

UniFlow SE Fume Hood 60” wide Unitized composite superstructure for total chemical resistance. non-metallic construction. Interior fume chamber one piece glass smooth, all coved corners for ease of cleaning. 5 year warranty. Unitized construction reduces weight for ease of installation.

Weight 265 lbs

Weight savings difference = 170 lbs |

|

|

| |

|

2. Disassembled Fume Hoods |

|

|

|

|

Traditional Fume Hood 60” wide 170 bolts, nuts and screws removed. 14 painted sheet metal panels with fasteners & brackets removed. 8 flat composite liner panels, no caulk to seal cracks, includes sash assembly & 36” fluorescent 2 bulb T-8 light fixture with steel painted white reflector.

Weight 435 lbs

UniFlow SE Fume Hood 60” wide Unitized

construction for superior durability and long life. Meets NFPA 45 for fire resistance in laboratories. Includes sash assembly & Vapor proof LED light fixture with polished Stainless steel reflector.

Weight 265 lbs

Weight savings difference = 170 lbs |

|

|

| |

|

3. Fume Chamber Composite Panels |

|

|

|

|

Traditional Fume Hood 60” wide 8 composite liner panels to fabricate fume chamber. No caulking or sealant in corner cracks. The ceiling panel shown with sheet metal vent outlet. Sash assembly and light assembly removed.

Weight 139 lbsUniFlow SE Fume Hood 60” wide Unitized composite superstructure for total chemical resistance. non-metallic construction. Interior fume chamber one piece glass smooth, all coved corners no joints. 5 year warranty. Unitized construction reduces weight for ease of installation. Sash assembly and light assembly removed.

Weight 210 lbs |

|

|

Customer Comments:

Hoods, based on the nature of the products we analyze (sulfur chlorides, sulfuric acids, oleums), last about two to three years. At the end of three years, the chemicals have corroded both the exterior steel panels and the internal steel frame work of the metal hoods. We replaced them eight years ago with HEMCO UniFlow fiberglass fume hoods the installation was easier and we have had no repairs since then. We are building a new facility, and we plan to install HEMCO hoods. Steve Mixon, Chief Chemist |

| UniFlow Fume Hood Chemical Applications |

| One Piece Integral Fume Chamber. Exterior composite FRP Super Structure for total chemical & corrosion resistance. Meets NFPA-45 fire resistance requirements, For use of plastics in laboratories. Any heat generating equipment should be elevated at least 3 inches above worksurface, and at least 3 inches away from side walls and baffle. |

|

|

|

| HEMCO FRP composite dual wall Superstructure unitized with integral FRP fume chamber. All fiberglass reinforced plastic side walls, rear wall, baffle system, air foil, exhaust collar, ceiling, with explosion proof light fixture. Available with Epoxy, Phenolic or Stainless steel worksurface. |

|

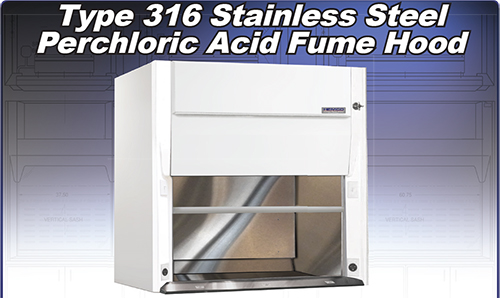

HEMCO HiPel FRP composite dual wall Superstructure unitized with integral stainless steel fume chamber. All 316 stainless steel side walls, rear wall, baffle system, exhaust collar, ceiling, with explosion proof light fixture. Integral recessed 316 stainless steel worksurface, air foil, and wash down system. |

|

|

|

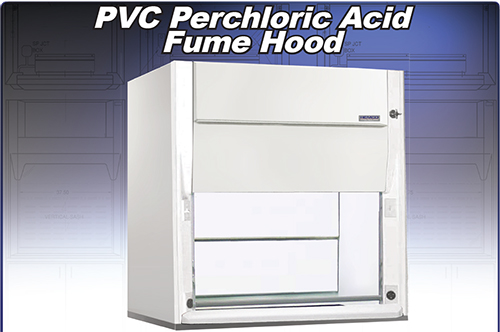

| HEMCO HiPel FRP composite dual wall Superstructure unitized with integral PVC fume chamber. All PVC side walls, rear wall, baffle system, exhaust collar, ceiling, with explosion proof light fixture. Integral recessed PVC worksurface, air foil, and wash down system. |

|

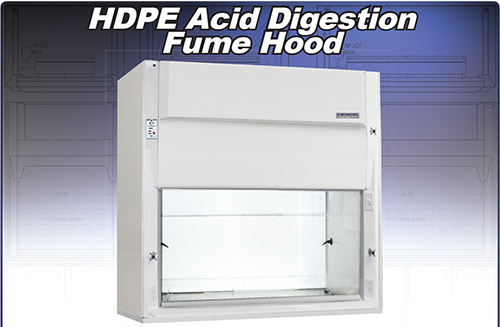

HEMCO FRP composite dual wall Superstructure unitized with integral HDPE fume chamber. HEMCO HDPE High Density Polyethylene side walls, rear wall, baffle system, air foil, exhaust collar, integral ceiling, with explosion proof light fixture. Integral High Density Polyethylene worksurface and air foil. |

|

|

|

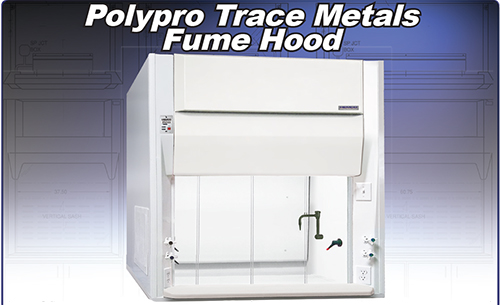

| HEMCO HiPel FRP composite dual wall Superstructure unitized with integral PolyPropylene fume chamber. All PolyPropylene side walls, rear wall, baffle system, air foil, exhaust collar, ceiling, with explosion proof light fixture. Integral recessed PolyPropyplene worksurface and air foil. |

|

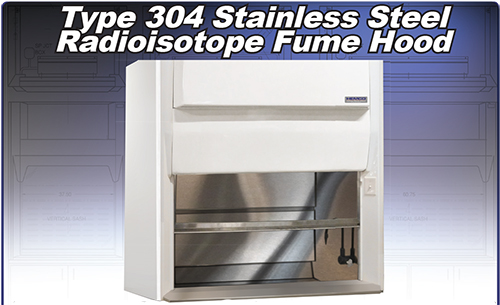

HEMCO HiPel FRP composite dual wall Superstructure unitized with integral 304 stainless steel fume chamber. All stainless steel side walls, rear wall, baffle system, air foil, exhaust collar, ceiling, with explosion proof light fixture. Integral recessed 304 stainless steel worksurface and air foil. |

|

Chemical Resistance Chart

UniFlow Fume Hoods are constructed of white composite Fiberglass Reinforced Polyester (FRP) material.

FRP is an excellent general purpose material for fume hood construction.

• Superstructure features unitized dual wall construction with integral one piece fume chamber for total chemical resistance,

non sparking construction, for hazardous locations.

• UniFlow HiPel FRP Composite construction is UL 1805 Classified for Laboratory Fume hoods and cabinets.

• HEMCO HiPel FRP composite conform to NFPA 45 for products used in laboratories.

• To provide for the best airflow performance through the fume chamber, any heat generating equipment should be elevated 2" to 3"

above work surface and 4" to 6" away from side walls and rear baffle system, and at least 6" away from the sash opening.

Chemical resistance of HEMCO’s most widely used FRP composite construction, and other liner material options.

|

N = No Effect ...........S = Slight Effect............... B = Bad Effect............... NA = Data Not Available

|

Worksurfaces |

| Chemical |

HEMCO HiPel FRP Composite |

Polyvinyl Chloride

(PVC) |

High Density

Polyethylene (HDPE) |

Polypropylene

(PP) |

304 Stainless Steel (SS) |

316 Stainless Steel (SS) |

Epoxy

Resin |

Phenolic

Resin |

| Acetic Acid |

N |

N |

NA |

N |

S |

N |

N |

NA |

| Acetone |

N |

B |

N |

N |

N |

N |

N |

NA |

| Ammonium Hydroxide |

N |

N |

NA |

N |

N |

N |

N (28%) |

NA |

| Benzene |

N |

B |

S |

B |

N |

N |

N |

B |

| Carbon Tetrachloride |

N |

B |

B |

B |

N |

N |

N |

N |

| Chromic Acid |

N |

B |

NA |

B |

N |

N |

S (40%) |

B |

| Diethyl Ether |

N |

S |

NA |

B |

N |

N |

N |

NA |

| Ethyl Alcohol |

N |

B |

N |

N |

N |

N |

N |

NA |

| Gasoline |

N |

N |

B |

NA |

N |

N |

N |

N |

| Hydrogen Peroxide |

N |

N |

N |

N |

NA |

NA |

N |

B |

| Hydrochloric Acid |

N |

N |

N |

N |

B |

B |

NA |

NA |

| Kerosene |

N |

N |

NA |

B |

N |

N |

B |

N |

| Methyl Alcohol |

N |

S |

N |

N |

N |

N |

N |

NA |

| Methyl Ethyl Ketone |

N |

B |

B |

NA |

N |

N |

N |

N |

| Nitric Acid |

N (20%) |

N |

N |

B |

B |

B |

N |

NA |

| Sodium Chloride |

N |

N |

N |

NA |

S (10%) |

N (10%) |

S (10%) |

N |

| Sodium Hydroxide |

N |

N |

N |

N |

N |

N |

S (10%) |

B |

| Sodium Hypochlorite |

N |

N |

B |

N |

N |

N |

N |

NA |

| Sodium Sulfide |

S |

N |

N |

NA |

N |

N |

NA |

B |

| Sulfuric Acid |

N (33%) |

N (70%) |

N (80%) |

N |

S (80%) |

N (80%) |

N (60%) |

B (75%) |

| Sulfuric Acid (conc.) |

S |

S |

S |

N |

B |

S |

B |

B |

| Flame Spread |

< 25 |

NA |

NA |

NA |

0 |

0 |

NA |

NA |

| Fuel Contributed |

0 |

NA |

NA |

NA |

0 |

0 |

NA |

NA |

| Smoke Developed |

500 |

NA |

NA |

NA |

0 |

0 |

NA |

NA |

|

Industries We Serve

• Life Sciences • Academic • Pharmaceutical • Chemical • Aerospace • Government • Research & Development •

• Forensics • Manufacturing • Engineering • Robotics • Safety • Petroleum • Coatings • Industrial • Automotive • Laboratory • HVAC •

• Quality Control • Electronics • Food Processing • Facility Maintenance • Spectroscopy • Health Care • Medical • Public Works •

• Water Treatment • Genetics • Correctional Institutions • Architects • Microscopy • Clinical • Packaging • Additive Manufacturing •

• Lasers • Loss

Prevention • Metal Fabricating • Filtration • Construction • Education • Energy • Environmental • Green Building •

• Photonics • Composites • Drug Development • Heavy Equipment • Mining • Nuclear • Pathology • |

|

|

|