|

| EnviroMax Technical Enclosures |

|

|

|

|

| EnviroMax Enclosures |

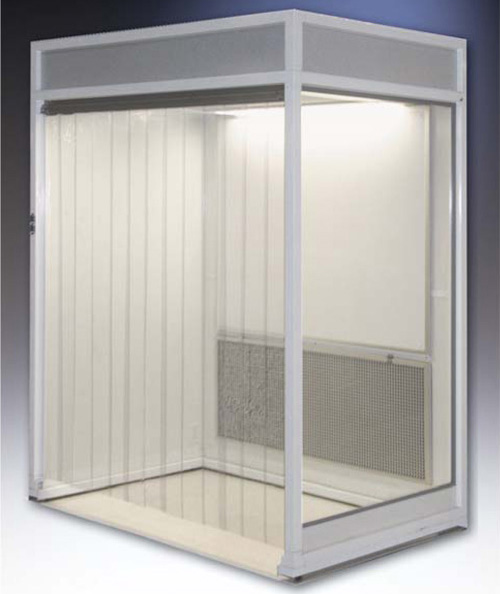

EnviroMax Vented Enclosures |

EnviroMax Laminar Flow Enclosures |

| Unitized & modular designs for exhausting fumes for Robotic and Automated processes. Vented or HEPA filtered available. |

Designed to protect personnel from potentially hazardous fumes. Enclosure can connect to in house exhaust system |

Engineered to meet critical clean specifications by isolating equipment and procedures to protect processes. |

|

|

|

|

| EnviroMax Enclosures |

C.C.S Enclosures |

EnviroMax Accessories |

| EnviroMax Enclosures designed to protect processes from surrounding contamination. |

Enclosure designed for the elimination of potentially hazardous vapors or particulate. |

Custom support benches, work surfaces, HEPA filtration, gauges, light fixtures, ducting, and blowers for EnviroMax. |

|

|

|

| EnviroMax Vented Enclosures protects personnel |

|

|

| |

|

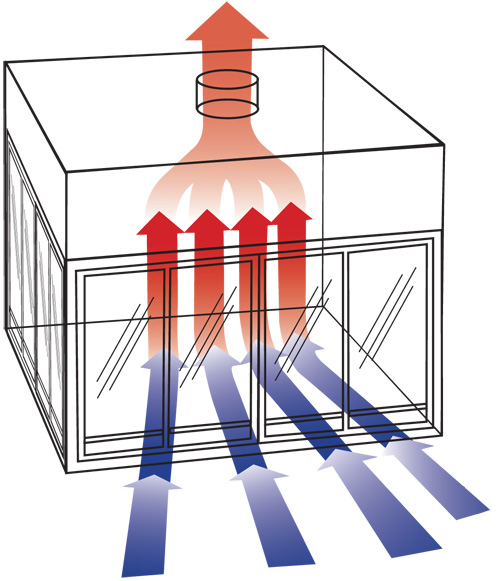

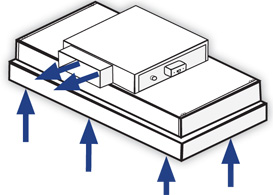

| A Vented Enclosure offered in Unitized & Modular Designs for exhausting fumes from Robotic & Automated processes |

Designed to protect personnel from potentially hazardous fumes, vapors and odors. The enclosure

can connect to in-house exhaust system or a dedicated exhaust blower, to provide the internal negative pressure needed to safely remove hazardous fumes from the work area. Air supply into the enclosure is supplied from the surrounding lab environment. |

| EnviroMax Options |

| • Access on any or all sides • Multi-Plug strips • Exhaust blowers • Vertical slide or Hinged doors • Base cabinets • Exhaust HEPA or Carbon filters • Other materials of construction • Anodized aluminum & stainless steel framing • Plumbing and electrical service fixtures • Airflow alarms • Support benches & work surfaces • |

| Contact us for custom enclosures built to your exact specifications |

|

| Unitized EnviroMax Vented Enclosure sizes 4’, 5’, 6’, & 8’wide by 30” & 36”deep by 46” high |

| Unitized Construction Sizes |

| Width |

Depth |

Height |

Cat .No. |

| 48" |

30" |

48" |

61041 |

| 60" |

30" |

48" |

61051 |

| 72" |

30" |

48" |

61061 |

| 96" |

30" |

48" |

61081 |

| 48" |

36" |

48" |

61042 |

| 60" |

36" |

48" |

61052 |

| 72" |

36" |

48" |

61062 |

| 96" |

36" |

48" |

61082 |

|

| Unitized design with depth of 30” and 36” to allow passage through doorways for easy

on-site setup.Viewing from all four sides of the enclosed system. Access to interior of enclosure, available from any or all sides. Vent duct sized to airflow requirements. Pre-wired electrical connection to single point junction box. Under the bench storage and shelving designed to suit your requirements.

Note: Custom sizes are welcomed. |

|

|

| EnviroMax enclosure unitized 120" wide X 36" deep X 48" high, with custom acid storage cabinets |

|

| Unitized EnviroMax Vented Enclosure |

Superstructure is welded steel framework with chemical resistant white powder coated finish. Side and rear walls are of clear acrylic or tempered glass. Ceiling is constructed of molded composite resin with the outlet duct connection collar sized for desired air volume. Slotted ceiling baffle allows air to flow evenly through the interior area into the exhaust

plenum. The front of the enclosure features horizontal sliding shatter-proof clear viewing

panels, (4) panels on (2) tracks allowing access at any position. Fluorescent light is factory

installed and sealed behind a clear lens. Light switch is mounted on the front post. Provides

an economical and flexible work space that exceeds stringent contamination requirements.

All electrical components are UL listed. |

|

| Modular EnviroMax Vented Enclosure sizes 6’, 8’, 10’ & 12’ wide by 48” & 60” deep by 46” high |

| Modular Construction Sizes |

| Width |

Depth |

Height |

Cat .No. |

| 72" |

48" |

48" |

62061 |

| 96" |

48" |

48" |

62081 |

| 120" |

48" |

48" |

62101 |

| 144" |

48" |

48" |

62121 |

| 72" |

60" |

48" |

62062 |

| 96" |

60" |

48" |

62082 |

| 120" |

60" |

48" |

62102 |

| 144" |

60" |

48" |

62122 |

|

Modular design with depth of 48” or 60” requires on-site assembly prior to setup and vent ducting. Pre-wired electrical connection to single point junction box. Work surface and support benches and cabinets sized to specifications. Provides an environment free of contamination for sensitive processes.

Note: Custom sizes are welcomed.

|

|

|

| EnviroMax Modular enclosure size: 60" wide X 60" deep X 96" high with work surface & 60" wide X 60" deep X 24" high support table. |

|

| Modular EnviroMax Vented Enclosure |

Superstructure is welded steel framework with chemical resistant white powder coated finish. Side

and rear walls are of clear acrylic or tempered glass. Ceiling is constructed of molded composite

resin with the outlet duct connection collar sized for desired air volume.

Slotted ceiling baffle allows air to be drawn out evenly across the width of the interior into the

exhaust plenum. The front of the enclosure features horizontal sliding tempered

glass panels, (4) panels on (2) tracks allowing access at any position. Fluorescent light is factory installed and sealed behind a clear lens. Light switch is mounted on the front header panel. All electrical components are UL listed. |

|

|

|

|

|

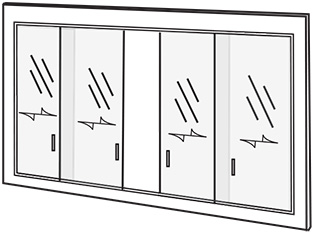

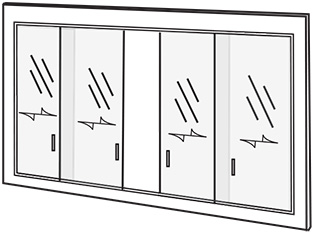

HORIZONTAL SASHES The standard sash for EnviroMax. The maximum sash opening for the horizontal sash is 1/2 that of the vertical sashes. The smaller opening, means less air exhausted resulting in energy savings. |

|

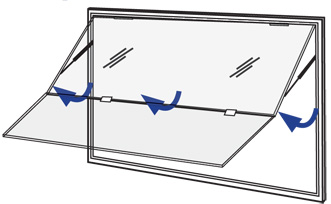

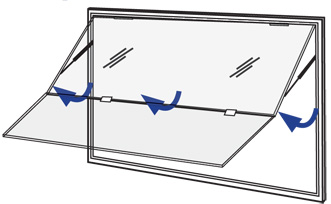

OPTIONAL HINGED SASHES Optional sash for EnviroMax. The sash may be hinged vertical rising or horizontal open for maximum access thru the fume chamber. |

|

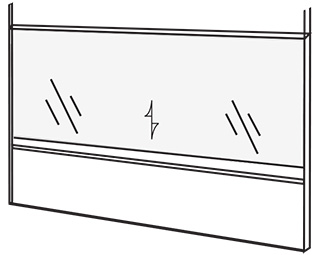

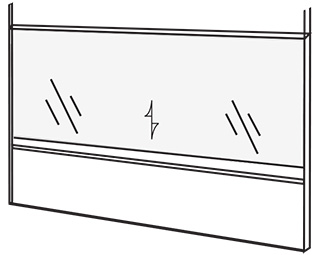

OPTIONAL COUNTER BALANCED VERTICAL SASHES The optional sash for EnviroMax. The sash may be lifted to the completely open position for maximum access through the fume chamber. Sash stops available. |

|

|

| EnviroMax HEPA Filtered Laminar Flow Enclosures |

|

|

|

EnviroMax HEPA filtered 96” wide X 48’ deep X 60”’ high horizontal sliding doors front & rear,hinged right & left side doors, heavy duty support table with seismic levelers |

|

Modular EnviroMax HEPA filtered laminar flow enclosure, sliding doors on front, size: 120”wide X 48”deep X 60” high, mobile table 30” high with epoxy shelf |

HEPA Filtered Clean Work Enclosures Laminar Flow Benches protects processes

|

|

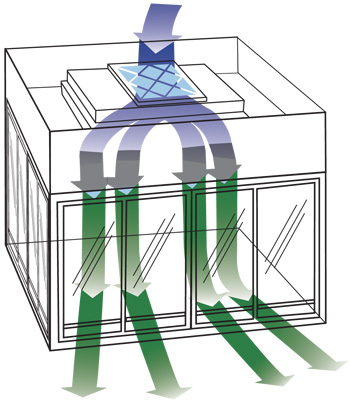

| A HEPA Filtered Enclosure offered in Unitized & Modular Design for Class 100 Clean Work Enclosure |

Specifically engineered to meet critical clean specifications by isolating equipment and procedures. The HEPA filtration eliminates particles 0.3 or larger to an efficiency of 99.995%, class 100 laminar airflow maintains a sterile work zone. Filters and lighting are conveniently changed from inside the enclosure.

Optional U.V. lighting, anti-static and grounding options are available. |

| EnviroMax HEPA Filtered Options |

| • Access on any or all sides • Multi-plug strips • Magnehelic gages • Cord port • base cabinets • Other materials of construction • Anodized aluminum & stainless steel framing • Electrical and key

lock services • Support benches & Work surfaces • |

| Contact us for custom enclosures built to your exact specifications |

|

| Unitized EnviroMax HEPA Filtered Clean Workstation. Sizes are 4’,5’,6’, & 8’ wide by 60” high |

| Unitized Construction Size |

| Width |

Depth |

Height |

Cat .No. |

| 48" |

30" |

60" |

63041 |

| 60" |

30" |

60" |

63051 |

| 72" |

30" |

60" |

63061 |

| 96" |

30" |

60" |

63081 |

| 48" |

36" |

60" |

63042 |

| 60" |

36" |

60" |

63052 |

| 72" |

36" |

60" |

63062 |

| 96" |

36" |

60" |

63082 |

|

Unitized design with depth of 30” and 36” to allow passage through doorways for easy on-site set-up. HEPA filters provide sterile clean airflow through work area with air returned to room space. Pre-wired electrical connection to a single point junction box. Work surfaces & support benches see below.

Note: Custom sizes are welcomed. |

|

|

| EnviroMax laminar flow enclosure size: 72" wide X 36" deep X 60" high with UV light & standard base table. |

|

| Unitized EnviroMax Specifications Clean Workstation |

Superstructure is welded steel framework with chemical resistant white powder coated finish. Side and rear walls are of clear acrylic or tempered glass. The front comes equipped with horizontal slide windows with air outlet slots on sides and front to

maintain positive pressure. HEPA filters are ceiling mounted in the enclosure and designed to maintain a minimum of class 100 environment. HEPA filters are 99.99% efficient at .3 micron HEPA filter module has an integral fan, prefilter, and speed

control. Fluorescent lighting is provided, switches are located on the front post.

Provides an economical and flexible work space that exceeds stringent

contamination requirements. All electrical components are U.L. listed. |

|

| Modular EnviroMax HEPA Filtered Clean Workstation. Sizes 6’, 8’, 10’& 12’ wide by 48” & 60” deep by 60” high |

| Modular Construction Sizes |

| Width |

Depth |

Height |

Cat .No. |

| 72" |

48" |

60" |

64061 |

| 96" |

48" |

60" |

64081 |

| 120" |

48" |

60" |

64101 |

| 144" |

48" |

60" |

64121 |

| 72" |

60" |

60" |

64062 |

| 96" |

60" |

60" |

64082 |

| 120" |

60" |

60" |

64102 |

| 144" |

60" |

60" |

64122 |

|

Modular design with depths of 48” & 60” for on-site assembly prior to setup and electrical connection. HEPA filters provide sterile clean airflow through work area and returned to room air space. Pre-wired electrical connection to single point junction box. Under the bench storage and shelving designed to suit your requirements.

Note: Custom sizes are welcomed.

|

|

|

| Unitized EnviroMax 96" wide X 36" deep X 60" high, base table 96" wide X 36" deep X 36" high, with sliding sashes front and back & side hinged sashes. |

|

| Modular EnviroMax Clean Workstation Enclosure |

| Superstructure is welded steel framework with chemical resistant white powder coated finish. Side and rear walls are of clear acrylic or tempered glass. The front comes equipped with horizontal slide windows with air outlet slots on sides and front to maintain positive pressure. HEPA filters are ceiling mounted in the enclosure and designed to maintain a minimum of class 100 environment. HEPA filters are 99.99% efficient at .3 micron. HEPA filter module has an integral fan, prefilter, and speed control. Fluorescent lighting is provided Switches are located on the front post. All electrical components are UL listed. |

|

| EnviroMax Sash Options |

Click for Maintenance Manual |

|

|

|

|

HORIZONTAL SASHES The standard sash for EnviroMax. The maximum sash opening for the horizontal sash is 1/2 that of the vertical sashes. The smaller opening, means less air exhausted resulting in energy savings. |

|

OPTIONAL HINGED SASHES Optional sash for EnviroMax. The sash may be hinged vertical rising or horizontal open for maximum access thru the fume chamber. |

|

OPTIONAL COUNTER BALANCED VERTICAL SASHES The optional sash for EnviroMax. The sash may be lifted to the completely open position for maximum access through the fume chamber. Sash stops available. |

|

|

| C.C.S. Floor Mounted Enclosures |

|

|

Features HEPA filtered air supplies and HEPA filtered exhaust air, to ensure a clean work zone free of contamination, protects work & environment. A safe change filter housing can be incorporated into the system if required. |

|

|

Floor mounted 96” wide X 96” deep X 108” high HEPA filtered supply & HEPA filtered exhaust |

|

Mobile Containment Control Systems 72” wide X 96” deep X 108” high, HEPA supply & HEPA exhaust air |

|

| Containment Control Systems provide enclosures for safe dispensing of powders to meet COSSH and GPM requirements. The C.C.S. can be designed to eliminate potential hazardous vapors or particulate where recirculation is not an option... |

• The C.C.S. is designed for the elimination of potentially hazardous vapors or

particulate in a non-recirculating exhaust system.

• Standard sizes are 6’ X 4’, 6’ X 6’, 8’ X 4’,and 8’ X6’.

Sizes can be customized to meet your laboratory needs.

• Fluorescent lighting, fans, gages, controls and electrical are provided.

• Floor mounted containment booths are available in either unitized (pre-assembled)

or modular (assembled on site) construction.

• On the front of the unit is a clear vinyl strip curtain that allows easy access to

move pallets or drums in and out. An air-gap underneath the vinyl strip

curtain ensures an inward flow of air, that sweeps across the floor.

• Extraction fans are automatically controlled to ensure near constant air flow

in-order to compensate for filter loading. |

|

|

Stationary Containment Control Systems 48” wide X 72” deep X 96” high, HEPA exhaust protects work and the environment |

|

|

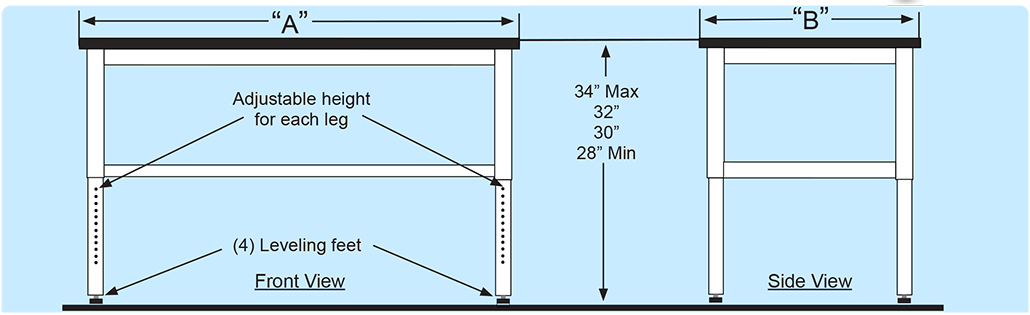

| EnviroMax Bench Stands & Worksurfaces |

|

|

• Available in 4’, 5’, 6’ & 8’ widths. Depths of 30” & 36”.

• Tested to 2000 lb. load capacity.

• Adjustable telescoping 2” square steel legs adjust

to 28”, 30”, 32” & 34” heights.

• Sturdy dual locking bolts on each leg.

• Height adjustable leveling legs on all four legs.

• Standard color: Lab White, (optional colors are available)

• SEFA Certified

• Black Phenolic Worksurface (not included) |

|

|

|

| Depth “B” |

Heavy Duty Tables |

| Width“A” |

| 48” |

60” |

72” |

96” |

| 30” |

54831 |

56031 |

57231 |

59631 |

| 36” |

54832 |

56032 |

57232 |

59632 |

| Epoxy Worksurfaces |

| 30” |

20425 |

20525 |

20625 |

20825 |

| 36” |

20435 |

20535 |

20635 |

20835 |

| Phenolic Worksurfaces |

| 30" |

20428 |

20528 |

20628 |

20828 |

| 36" |

20438 |

20538 |

20638 |

20838 |

| Casters (4) Heavy Duty, with 2 locking Cat.No. 54444 |

|

|

T - Frame Mobile Tables

The table is adjustable from 30 to 36 inches in height. Is is of welded steel construction with a phenolic resin work surface. |

|

Mobile table is an ideal lab cart and can accommodate: |

• MicroFlow I, II & III Workstations |

• Demonstration Hoods

|

• VSE Vented Safety Enclosures |

• Table Top Fume Hoods |

|

• Welded all steel construction, chemical resistant

epoxy powder coated finish color white. |

• (2) locking casters & (2) Non-locking Casters included |

• Phenolic resin worksurface |

| Mobile Table 36” wide |

50318 |

| Mobile Table 48” wide |

50418 |

|

|

|

|

| Magnehelic Gauge Options |

|

|

|

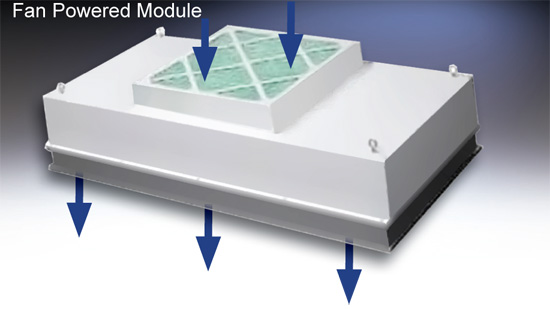

Fan Powered HEPA Module in sizes: 24” X 24”, 24” X 48”, 24” X 72” |

|

|

• Module is 99.99% efficient.@ 0.3 micron HEPA filter,with 90 FPM @ initial 0.47 w.g., 115v low watt A/C, 60Hz 1ph, includes prefilter, on/off/variable speed control, powder coated steel housing.

• HEPA filters can be changed from inside the enclosure, without removing the unit from the ceiling, Can be ordered with optional integral lighting.

Filter units feature an upstream gel channel on the final filter which provides a leak-free seal between the filter and the housing. |

| Size |

With Lights |

Without Lights |

| 24" X 24" |

50122 |

50322 |

| 24" X 48" |

50124 |

50324 |

| 24" X 72" |

50126 |

50326 |

|

|

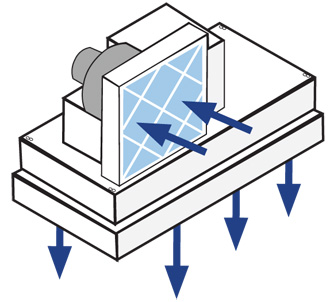

| Explosion Proof Module |

|

Unit features a 24” X 48”, 99.99% efficient HEPA filter, prefilter, spark resistant fan, filter change from the inside of the enclosure.

Cat. No. 50424

|

|

| HEPA Exhaust (Ductless) |

|

Reverse flow HEPA filter module draws air out through the HEPA filter and discharges air back to lab. 24” X 48” 99.99% efficient HEPA filter

|

| Fan Powered HEPA Module |

| Size |

With Lights |

With Out Lights |

| 24" X 24" |

50232 |

50332 |

| 24" X 48" |

50234 |

50334 |

|

|

| Replacement Filters |

| Replacement Filters Description |

Cat. No. |

| Prefilter, 30% efficient 20” X 20” X 1” |

52190 |

HEPA filter 99.99% efficient (Inside Replaceable)

(for 24” X 24” module) |

52201 |

| HEPA filter 99.99% efficient (Non Inside Replaceable) (for 24” X 24” module) |

52070 |

HEPA filter 99.99% efficient (Inside Replaceable)

(for 24” X 36” module) |

52214 |

| HEPA filter 99.99% efficient (Non Inside Replaceable) (for 24” X 36” module) |

52013 |

HEPA filter 99.99% efficient (Inside Replaceable)

(for 24” X 48” module) |

52200 |

| HEPA filter 99.99% efficient (Non Inside Replaceable) (for 24” X 48” module) |

52090 |

|

| HEPA or Carbon Exhaust (Ducted) |

|

Housing features a hinged access door for either HEPA or carbon filter change out. For exhaust requirements to 1000 cfm. Housing is installed on roof of enclosure. |

| Fan Powered HEPA Module |

| Size |

Housing with Filter |

Replacement Filter |

| HEPA Filter |

50189 |

50095 24" X 24" X 12" |

| Carbon Filter |

50298 |

52101 24" X 24" X 12" |

| Prefilter ctn of (6) |

-- |

52001 24" X 24" X 12" |

|

|

|

| EnviroMax Electrical Options |

Fluorescent Lighting Fluorescent Lighting

Standard 4’ T-5,(2) bulb, 115V, with bulbs changed from the outside. Bulbs are

not included. UL listed 24”Cat. No. 50224

36” Cat. No. 50236

48” Cat. No. 50248 |

Vapor Proof

Lighting

Fluorescent fixture,

(2) tube T-8, 115V,

with white steel

reflector and

changed

from the outside.

UL listed. 48”

Cat. No. 50348 |

|

Explosion-Proof

Light Std

for use in

hazardous

locations. 115V or

230V.bulb not

included. Factory

installed but

not wired.

UL listed.

Class I Div II,

Groups A,B,C,D,

Class II Div II

Groups F&G.

Cat. No. 50034 |

|

|

Explosion-Proof Fixture

For use in hazardous locations. Gray, two coat epoxy finish with easily removed

prismatic globe. Accepts long neck bulb up to 300 watts, (bulb not included)

115 / 230V. Factory mounted, not wired. UL listed. Class I

Div I Group C, D, Class II Div I Group E, F & G

Cat. No. 50038 |

Multi-Plug Chase

Anodized aluminum raceway can be supplied with a variety of electrical or data services. |

• Specify length, type of plug, quantity of plugs, type of data outlet. |

|

|

|

Electrical Pedestal Boxes

Brushed cast aluminum box with stainless steel cover. Please specify desired location of pedestal box. |

| |

Single Gang |

Double Gang |

Single Face

|

Double Face |

Single Face

|

Double Face |

| Duplex/115 V/15a |

50131S |

50131D |

50031S |

50031D |

| Single/230 V/20a |

50132S |

50132D |

50032S |

50032D |

| GFI Duplex/115 V/20a |

50135S

|

50135D |

50033S |

50033D |

| One Duplex and One Single / 250 V/20a |

50034S |

50034D |

|

|

|

UV Ultraviolet Lighting for use in hazardous locations. Single tube 115V or 230V. UL listed. Polished stainless steel reflector

Cat .No. 50348 |

|

|

|

|

|

|

Duplex Receptacle

115V single phase receptacle. Installed on front column of fume hood. Includes junction box and cover plate. UL listed.

| amps |

Cat. No. |

| 15 amps |

50029-1 |

| 20 amps |

50029-2 |

|

Single Receptacle

230V single phase receptacle. Installed on front column of fume hood. Includes junction box and cover plate. UL listed.

| amps |

Cat. No. |

| 15 amps |

50030-1 |

| 20 amps |

50030-2 |

|

GFI Duplex

115V consists of combination ground fault interrupters, 3-wire polarized grounded. Includes junction box & cover plate.

| amps |

Cat. No. |

| 15 amps |

50048-1 |

| 20 amps |

50048-2 |

|

Data Port

Cat 6, 10 gigabit ethernet, (2) port fixture. Installed on front column. Cabling not included.

Cat No. 50053

|

|

|

|

Keycock

Fixture includes turret and shank connection. |

| Single Outlet |

50014 |

| Double Outlet |

50014-2 |

| Triple Outlet |

50014-3 |

| Quad Outlet |

50014-4 |

|

|

|

Epoxy or Sinks

Chemical resistant sinks are molded with integral flanges allowing drop-in mounting. Sinks include 1 1/2” IPS threaded outlet. Please specify location in counter top layout of A and B dimensions. |

| Epoxy Resin Sinks |

| A |

B |

Depth |

Cat. No. |

| 9” |

6” |

6” |

42021 |

| 16” |

12” |

8” |

42022 |

| 18” |

15” |

11” |

42026 |

| 24” |

16” |

8” |

42027 |

|

|

|

Deck Mounted

Mixing Faucet

Hot and cold water faucet.

6” gooseneck. 3/8” NPT.

Cat. No. 50026 |

|

EnviroMax Ducting Accessories

Ducting and accessories are chemical resistant and easy to install |

| Flexible and Rigid PVC Ducting |

4” |

6” |

8” |

10” |

12” |

14” |

|

1. Flexible Ducting neoprene impregnated fiberglass reinforced with steel helix wire. Standard 12’ lengths. Each piece includes two strap clamps. |

Cat.

No.

80051 |

Cat.

No.

80052 |

Cat.

No.

80053 |

Cat.

No.

80054 |

Cat.

No.

80055 |

Cat.

No.

80056 |

|

2. PVC Rigid Ducting chemical resistant for permanent installations. Standard 10’ lengths with straight ends. |

Cat.

No.

82004 |

Cat.

No.

82006 |

Cat.

No.

82009 |

Cat.

No.

82011 |

Cat.

No.

82013 |

Cat.

No.

82015 |

|

3. PVC Coupling required to connect straight sections. |

Cat.

No.

82147 |

Cat.

No.

82149 |

Cat.

No.

82153 |

Cat.

No.

82157 |

Cat.

No.

82159 |

Cat.

No.

82160 |

|

4. PVC 90 degree Elbow used in order to offset obstacles. Has belled ends for duct connections. |

Cat.

No.

82060 |

Cat.

No.

82061 |

Cat.

No.

82063 |

Cat.

No.

82066 |

Cat.

No.

82068 |

Cat.

No.

82069 |

|

5. PVC 45 degree Elbow used in order to offset obstacles. Less static pressure loss than a 90 degree elbow. Has belled ends for duct connections. |

Cat.

No.

82082 |

Cat.

No.

82083 |

Cat.

No.

82085 |

Cat.

No.

82087 |

Cat.

No.

82089 |

Cat.

No.

82090 |

|

6. PVC 45 degree WYE lateral for joining common ductwork in multiple hood designs. Branch diameter may be sized to 2” to 4” smaller than main diameter. Has belled ends for duct connections. |

Cat.

No.

82216 |

Cat.

No.

82218 |

Cat.

No.

82226 |

Cat.

No.

82229 |

Cat.

No.

82233 |

Cat.

No.

82234 |

|

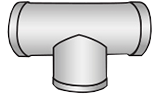

7. PVC Tee used in manifold exhaust systems. Has belled ends for duct connection. |

Cat.

No.

82034 |

Cat.

No.

82036 |

Cat.

No.

82038 |

Cat.

No.

82040 |

Cat.

No.

82044 |

Cat.

No.

82046 |

|

8. PVC Butterfly Damper modifies cfm

for single or multiple hood

arrangement. Has belled ends for duct connection. |

Cat.

No.

82450 |

Cat.

No.

82452 |

Cat.

No.

82454 |

Cat.

No.

82456 |

Cat.

No.

82458 |

Cat.

No.

82460 |

|

9. PVC Blast Gate Damper a gate that slides in and out to control cfm. Has belled ends for duct connection. |

Cat.

No.

82369 |

Cat.

No.

82371 |

Cat.

No.

82373 |

Cat.

No.

82375 |

Cat.

No.

82377 |

Cat.

No.

82379 |

|

10. PVC Rain Skirt slips over straight pipe on roof to slope water away from cutout. |

Cat.

No.

82328 |

Cat.

No.

82330 |

Cat.

No.

82332 |

Cat.

No.

82334 |

Cat.

No.

82336 |

Cat.

No.

82337 |

|

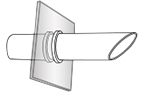

11. PVC Vent outlet for horizontal venting through wall or window. Angled end prevents rain from entering.

Male connector included. |

Cat.

No.

80074 |

Cat.

No.

80076 |

Cat.

No.

80077 |

Cat.

No.

80078 |

Cat.

No.

80079 |

Cat.

No.

80080 |

|

12. Zero Pressure Weather Cap discharges fumes vertically away from roof. Self-draining. Minimal static pressure loss. This is the recommended weather cap. |

Cat.

No.

82350

“A”=16” |

Cat.

No.

82352

“A”=24” |

Cat.

No.

82354

“A”=32" |

Cat.

No.

82356

“A”=40" |

Cat.

No.

82358

“A”=48” |

Cat.

No.

82359

“A”=56” |

|

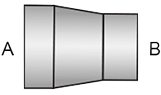

13. Round to Round Transition to smaller duct diameter. |

Cat.

No.

82613

4"- 6" |

Cat.

No.

82615

6"- 8" |

Cat.

No.

82617

8"- 10" |

Cat.

No.

82619

10"- 12" |

Cat.

No.

82620

12"- 14" |

Cat.

No.

82621

14"- 16" |

|

| EnviroMax Enclosure Blowers |

|

| A complete line of belt and direct drive exhaust blowers that are chemical resistant & available in standard and explosion-proof models. HEMCO blowers are designed to operate effectively and efficiently to remove noxious & hazardous fumes. Standard 115V 60Hz international electrical configuration of 220V 50Hz AC available. |

|

|

1. Blowers should be mounted on the roof in-order that the ducting leading to the blower inlet is under negative static pressure. If exhaust blowers are mounted inside the building, all ducting connected to the blower outlet will be under positive static pressure, if a leak were to develop in the section of the duct inside the building, toxic & or hazardous fumes could be forced out of the ductwork and into that area of the building.

2. To achieve the lowest practical noise level in the exhaust system, we suggest that the following measurements be

used when there is no conflict with

other specifications

of the system:

a. Use vibration isolators or mounting blower exhaust assembly.

b. Install a blower fan that will deliver the correct CFM and

static pressure with the lowest practical impeller wheel RPM.

If possible, use a duct size large enough to keep duct velocity under 1800 FPM velocity.

c. Use a flexible connection at the fan inlet to isolate mechanical transmission of noise from the ducting between the hood and the exhaust blower. |

|

d. Exhaust blower system should be designed with the fewest possible elbows or other fittings. Use radius type elbows & avoid using square elbows. Use gradual tapered transitions where necessary, & avoid abrupt changes in configuration or cross sectional area.

3. When ordering an exhaust blower, specify the orientation of discharge desired. Vertical up blast discharge is the most common and will be supplied unless otherwise specified.

4. All fans are shipped with clockwise rotation when viewed from the motor end of the assembly.

5. For normal usage, the standard for both the blower housing and impeller wheel is epoxy coated.

6. Blowers used for hood exhaust at altitudes above 1,000 feet, may require a correction factor to provide the correct CFM and static pressure.

Contact factory for details relating to your specific application. |

|

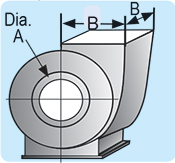

| Epoxy Coated Steel Blower Belt Drive |

|

|

Standard (STD) belt drive steel blower and impeller wheel are epoxy coated for superior chemical resistance. Explosion-proof blowers (EXP) have epoxy coated, non-sparking aluminum impeller wheel. V-belt drive and adjustable pulleys permit field balancing. Seven discharge positions to suit installation. Weather housing is furnished. Motor has thermal overload protection. Specify: 115 V single phase, 230 V single phase, 230/460 V three phase or 208 V (consult factory). 1 year manufacturer’s warranty |

| Catalog Number and Static Pressure |

| cfm |

A

Inlet

Diameter |

B

Outlet

Size |

1/2” Static Pressure |

3/4” Static Pressure |

1” Static Pressure |

1 1/2” Static

Pressure |

| HP |

STD |

EXP |

HP |

STD |

EXP |

HP |

STD |

EXP |

HP |

STD |

EXP |

| 296 |

8 7/8” |

10 1/8” x 4 1/8” |

1/4 |

51701 |

51801 |

1/4 |

51702 |

51802 |

1/4 |

51703 |

51803 |

1/4 |

51704 |

51804 |

| 474 |

8 7/8” |

10 1/8” x 4 1/8” |

1/4 |

51705 |

51805 |

1/4 |

51706 |

51806 |

1/4 |

51707 |

51807 |

1/2 |

51708 |

51808 |

| 652 |

8 7/8” |

10 1/8” x 6 3/8” |

1/2 |

51709 |

51809 |

1/2 |

51710 |

51810 |

1/2 |

51711 |

51811 |

1/2 |

51712 |

51812 |

| 800 |

8 7/8” |

10 1/8” x 6 3/8” |

1/2 |

51713 |

51813 |

1/2 |

51714 |

51814 |

1/2 |

51715 |

51815 |

3/4 |

51716 |

51816 |

| 914 |

9 7/8” |

11 1/2” x 8 1/4” |

1/2 |

51717 |

51817 |

3/4 |

51718 |

51818 |

-- |

-- |

-- |

-- |

-- |

-- |

| 1044 |

9 7/8” |

11 1/2” x 8 1/4” |

1/2 |

51719 |

51819 |

1/2 |

51720 |

51820 |

1/2 |

51721 |

51821 |

-- |

-- |

-- |

| 1175 |

9 7/8” |

11 1/2” x 8 1/4” |

1/2 |

51722 |

51822 |

1/2 |

51723 |

51823 |

3/4 |

51724 |

51824 |

-- |

-- |

-- |

| 1240 |

9 7/8” |

11 1/2” x 8 1/4” |

1/2 |

51725 |

51825 |

1/2 |

51726 |

51826 |

3/4 |

51727 |

51827 |

3/4 |

51728 |

51828 |

| 1240 |

11 7/8” |

13 3/8” x 8 1/4” |

1/3 |

51729 |

51829 |

1/2 |

51730 |

51830 |

-- |

-- |

-- |

-- |

-- |

-- |

| 1506 |

11 7/8” |

13 3/8” x 8 1/4” |

3/4 |

51731 |

51831 |

3/4 |

51732 |

51832 |

3/4 |

51733 |

51833 |

-- |

-- |

|

| 1771 |

11 7/8” |

13 3/8” x 8 1/4” |

1 |

51734 |

51834 |

1 |

51735 |

51835 |

1 |

51736 |

51836 |

1 1/2 |

51737 |

51837 |

|

|

|

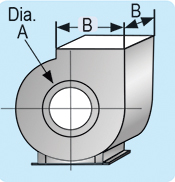

| Epoxy Coated Steel Blower Direct Drive |

|

|

Direct drive steel blower and impeller wheel are epoxy coated for superior chemical resistance. Explosion proof blowers have epoxy coated non-sparking aluminum impeller wheels. Motor is 115V, 1 phase and has thermal overload protection. 1 year manufacturer’s warranty |

| Catalog Number and Static Pressure |

A

Inlet

Diameter |

B

Outlet

Size |

HP |

STD |

EXP |

1/4” SP |

1/2” SP |

3/4” SP |

1” SP |

| cfm |

cfm |

cfm |

cfm |

| 6” |

7” X 4-3/8” |

1/6 |

51177 |

51178 |

565 |

515 |

440 |

300 |

| 8” |

8-3/4” X 5-7/16” |

1/3 |

51179 |

51180 |

935 |

875 |

800 |

712 |

| 9” |

10-1/8” X 4-1/8” |

1/2 |

51181 |

51182 |

1050 |

980 |

920 |

850 |

| 9” |

10-1/8” X 5-1/8” |

3/4 |

51183 |

51184 |

1260 |

1220 |

1180 |

1100 |

|

|

| Standard motors are 115V, 60Hz / 1 phase. Explosion proof motors are 115/230V, 60Hz, 1 phase. Other voltage, hertz, and phase motors are available. |

|

| Fume Hood Exhaust Blowers Ordering Info |

|

| HEMCO offers a complete line of chemical resistant non-metallic exhaust blowers in belt drive or direct drive options in standard or explosion proof models. Ideal for applications where corrosion resistance is critical. These blowers are available in polypropylene or fiberglass construction. |

|

|

1. It is recommended that exhaust blowers be located at the

end of

the ducting which is typically roof mounted. This ensures a negative pressure through out the ventilation system. However for applications

where the duct is going directly out through a wall above a fume hood,one option is to have a fiberglass direct drive blower installed in the top of the fume hood. By having the blower internally mounted, the installation is simplified and convenient for duct connection and servicing. However there would be an airflow sound element associated to having the blower hood mounted.

|

|

2. By keeping the exhaust duct as short and as straight as possible,

the total resistance will be reduced and by keeping the diameter of

the duct correctly sized to the flow volume, noise and static

pressure can be reduced.

3. Blower wheels for polypropylene and fiberglass blowers are polypropylene.

4. Vibration isolators are recommended when mounting the

blower assemblies

5. HEMCO recommends that a sash stop be installed on the fume hood to limit the sash height for operation. By having

stop at a half open position, the total CFM can be reduced by 50%; thus by reducing the volume, energy loss, duct diameter, motor and blower size, and sound is reduced. |

|

|

| UniFlow SE & LE Fume Hoods |

Hood

Width |

Hood

Depth |

Full

Open cfm |

1/2

Open cfm |

| 36” |

30” |

438 |

241 |

| 48” |

30” |

772 |

385 |

| 60” |

30” |

938 |

474 |

| 72” |

30” |

1162 |

592 |

| 96” |

30” |

1613 |

800 |

| UniFlow CE Fume Hoods |

Hood

Width |

Hood

Depth |

Full

Open cfm |

1/2

Open cfm |

| 30” |

24” |

378 |

189 |

| 36” |

24” |

460 |

230 |

| 48” |

24” |

654 |

327 |

| 72” |

24” |

960 |

480 |

|

• CFM at 100 fpm face velocity

• Housing is constructed of heavy gauged galvanized steel, with a baked enamel

finish, to resist weather & chemical exposures.

• Flange inlet collars enable easy connection to ductwork.

• Wheel is dynamically balanced to minimize noise and increase efficiency.

• Ball bearing pillow blocks are per-lubricated and resistant to both moisture & dirt.

• Shaft is constructed of polished steel with a coating to prevent rust and corrosion.

• Motors meet NEMA standards for single speed motors.

• These blowers are ideally suited for both supply and exhaust applications in

laboratories, educational, pharmaceutical, industrial, and other applications. |

|

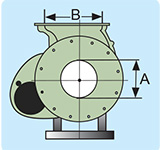

| Polypropylene Belt Drive Blowers |

|

|

High efficiency impellers produce low power consumption, reduced operating costs and quiet operation. 20 forward curved blades, in fire retardant polypropylene. Non-static and oil resistant v-Belt, cast iron pulleys, adjustable pulleys available, adjustment for tensioning and belt replacement. 230V explosion proof, non sparking, chemical resistant for hostile or hazardous environments. 115V single phase or three phase. Non-static and oil resistant V-belt, cast iron pulleys, adjustable pulleys available, adjustment for tensioning and belt replacement.

1 year manufacturer’s warranty |

|

| Catalog Number and Static Pressure |

| cfm |

A

Inlet

Diameter |

B

Outlet

Diameter |

0.5” Static Pressure HP |

0.75” Static Pressure HP |

1.0” Static Pressure HP |

| HP |

STD |

EXP |

HP |

STD |

EXP |

HP |

STD |

EXP |

| 400 |

6” |

6” |

1/4 |

51450 |

51850 |

1/4 |

51460 |

51860 |

1/4 |

51470 |

51870 |

| 800 |

8” |

8” |

1/4 |

51451 |

51851 |

1/3 |

51461 |

51861 |

1/3 |

51471 |

51871 |

| 1000 |

8” |

8” |

1/2 |

51452 |

51852 |

1/2 |

51462 |

51862 |

1/2 |

51472 |

51872 |

| 1200 |

10” |

10” |

1/2 |

51453 |

51853 |

1/2 |

51463 |

51863 |

1/2 |

51473 |

51873 |

| 1600 |

10” |

10” |

1 |

51754 |

51854 |

1 |

51464 |

51864 |

1 |

51474 |

51874 |

|

|

| Variable Motor Speed Drive |

|

.jpg) |

|

Motor speed control can be used to manually adjust blower cfm. Adjustable speed control for 3-phase motors 3/4 to 10 horsepower at 230/460 volts and 50/60Hz. these drives provide high operation efficiency and constant input power factor throughout the entire speed range of 3 to 60Hz. Drives are rugged, reliable and backed by years of manufacturing and application experience in motors and controls. These drives are tailored to the variable torque loads in fans or fume hoods.

1/2 -5HP 230V 3ph, 50/60 Hz.....................................................................................Cat.No. 51402 |

|

|

|

| Laminar Flow Fume Hoods / Clean Work Stations are designed to protect equipment or processes from contamination, by providing a HEPA filtered Class 100 environment. The workstation has user friendly clear acrylic side walls, convenient hinge-up front viewing window, and fluorescing lighting with all controls front mounted. Unit includes 115v power cord for immediate set-up and operation. |

|

|

|

|